Our Portfolio of All-in-one, Fast, Quiet, Waterproof, Linear Actuators

%20v2%20.png)

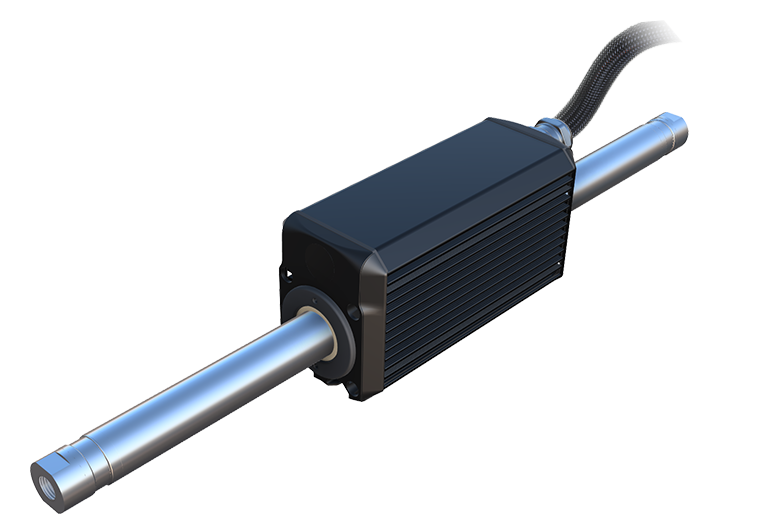

ORCA-6-LITE

affordable

| Max Stall Power |

325 W |

| Max Stall Force |

246 N 55.5 lbf |

| Max Speed |

1.3 m/s 51 in/s |

| Force Accuracy |

±0.74 N 0.17 lbf |

| Position Accuracy |

±150 μm ±0.0059 in |

ORCA-6-24V

high speed

| Max Stall Power |

899 W |

| Max Stall Force |

426 N 95.7 lbf |

| Max Speed |

3.8 m/s 148 in/s |

| Force Accuracy |

±0.57 N 0.13 lbf |

| Position Accuracy |

±150 μm ±0.0059 in |

ORCA-6-48V

high stall forces

| Max Stall Power |

2023 W |

| Max Stall Force |

638 N 143 lbf |

| Max Speed |

2.5 m/s 99 in/s |

| Force Accuracy |

±0.64 N 0.14 lbf |

| Position Accuracy |

±150 μm ±0.0059 in |

ORCA-15-48V

very high stall forces

| Max Stall Power |

2250 W |

| Max Stall Force |

1061 N 238 lbf |

| Max Speed |

1.5 m/s 60 in/s |

| Force Accuracy |

±0.97 N 0.22 lbf |

| Position Accuracy |

±150 μm ±0.0059 in |

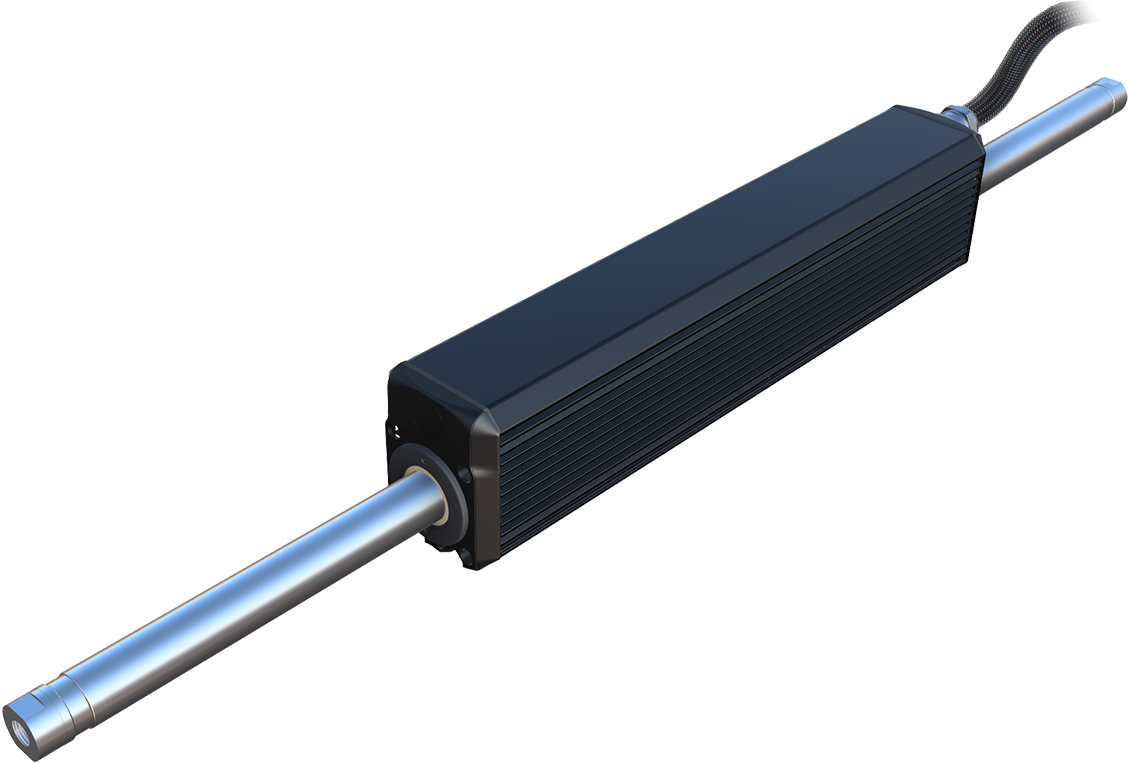

Orca Series Linear Motor Datasheet [PDF]

For Engineering Drawings, CADs, Reference and User Manuals, please visit our Downloads page.

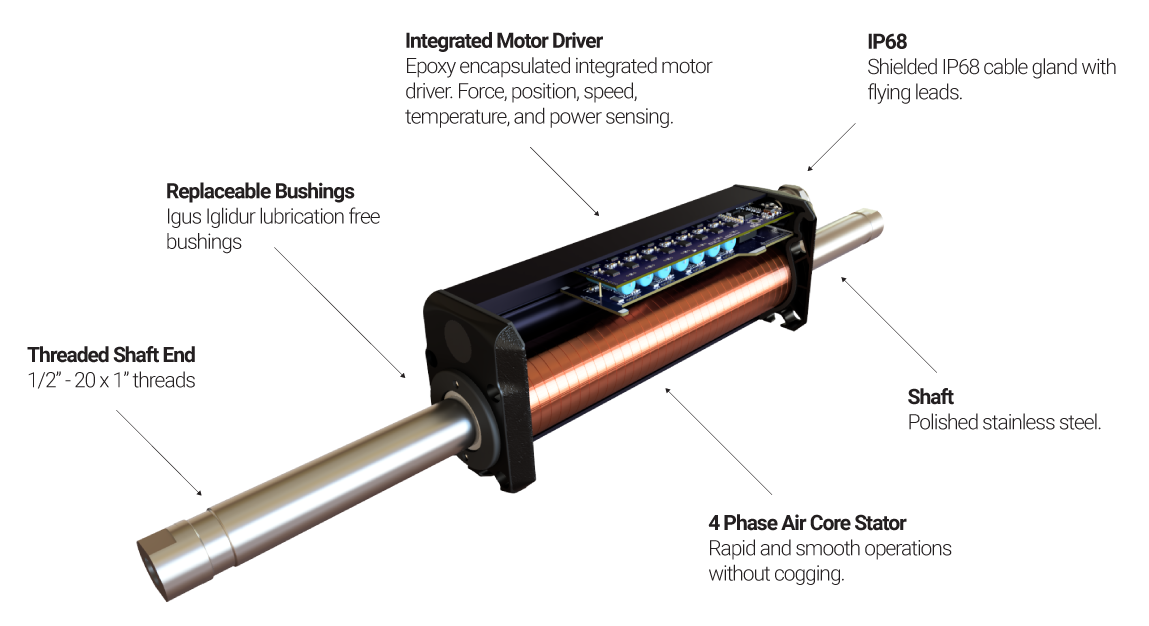

Features

Fully Integrated

Our motors all include integrated power delivery, four-phase motor drivers, logic, and a suite of sensors. The benefit of this approach is two-fold:

Firstly, all components are calibrated at the time of manufacturing which increases performance and simplifies integration into your existing infrastructure.

Secondly, removing the need to install several separate components and ensure they are all configured to interact with each other correctly dramatically reduces installation overhead.

Integrated sensing includes force, position, and temperature.

Exploded Render of an Orca Series Motor

Force Control

Traditional motors are position or velocity controlled. This means their logic controllers deliver commands to move to a specific position or at a specific velocity. Our motors are inherently force controlled which means they can feel the force they are imparting. This is a critical safety feature in applications where that force is imparted upon a person as our motor will know when it encounters an object and can back off or apply lower force.

Silent

With the quietest motors on the market, we facilitate easier integration into environments that people share. Lower noise levels in industrial settings are safer and less fatiguing for humans. Simulation and entertainment applications benefit from deeper immersion with no need for the implementation of music or sound effects to cover the noise of the motors.

Integrated Kinematic Control

Our Windows Based Application Tuning a Kinematic Profile

Orca Series motors are equipped with a kinematic controller that allows motion profiles to be saved directly to the motor. These profiles allow movement to a shaft position over a specified period of time. Kinematic motions can be triggered using software or by a hardware trigger, such as a button or signal. Up to 32 motions can be saved to a single Orca Series motor.

Low Latency

On-board advanced microprocessors and integrated sensing allow for sub-millisecond control loop times. This is a critical feature in virtual reality (VR) applications such as simulation as slower control loop timing leads to nausea in riders.

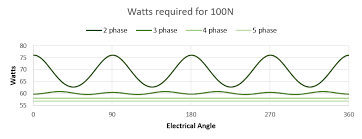

High Performance Four-Phase

Plot Illustrating Efficiency of 4-Phase Motor Geometry

Iris Dynamics’ unique four phase motor geometry, combined with our proprietary software, allows our motors to generate linear force throughout the entire stroke without any of the cogging or grain that plagues other motors. All our motors are fully back driveable. Our onboard sensing and feed forward control algorithms allow the motors to move with very high levels of precision in position and velocity.